Applications

APPLICATIONS

LEGIONELLA PREVENTION FOR HOT AND COLD WATER SYSTEMS

Legionella has been identified as a major problem in multi-storey buildings such as hotels, hospitals, hostels, schools, military installations, nursing homes and office buildings.

Worldwide, thousands of people become seriously ill or die from this potentially fatal disease. The costs of contaminating a building’s water system can be considerable not only in terms of human suffering, but also financially. If the hotel is identified as the source of the infection, it could lead to forced closure while the problem is dealt with and possible lawsuits if people are infected. This means a significant loss of income and reputation. In addition, in many countries, if it is proven that the problem was caused by the negligence of the operators and staff of the hotel or ship, it can lead to large financial penalties or even prison terms for those involved. Every year, hotels around the world are forced to close due to this problem, often at the height of the tourist season. Every year, people die not from a disease treated in hospitals, but from an infection caused by this deadly bacteria they get from the hospital’s water. Due to the sharp increase in energy prices, many operators of these buildings lower the overall temperature of the domestic water system, which can increase the risk of Legionella infection.

Finanolyte anolyte generators can be installed in any of these buildings or ships for continuous treatment of the water system, eliminating not only the risk of contamination, but also the risk of reinfection.

Our anolyte generators give building and ship operators peace of mind that they are doing everything they can to protect building occupants or passengers from infection, thus minimizing their own financial and legal risks.

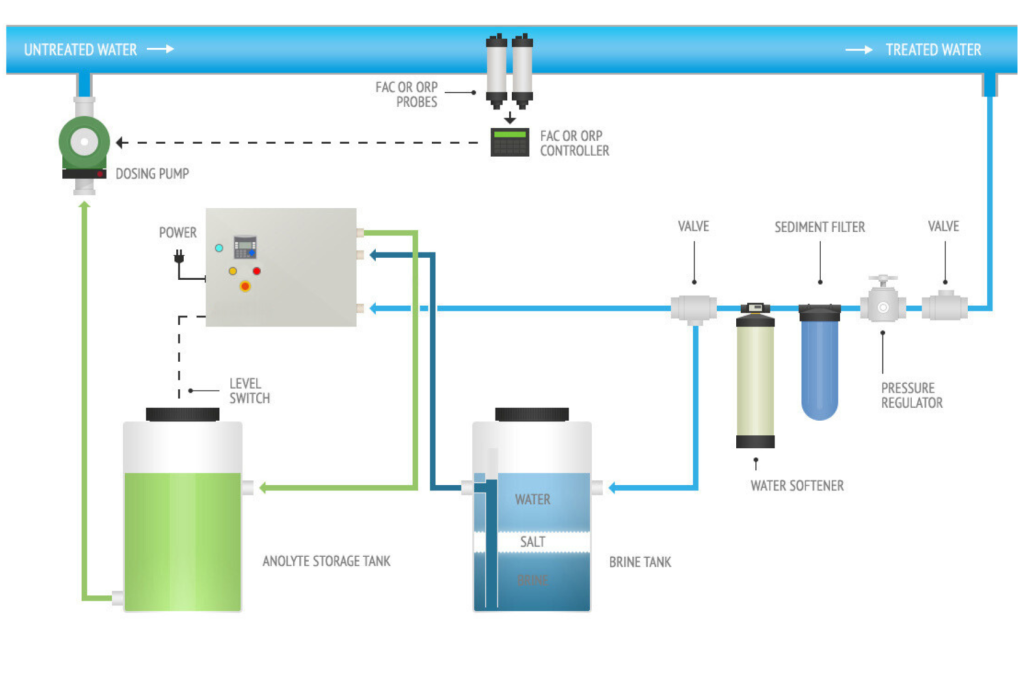

Drawing of a typical Finanolyte Water Disinfection System (EWDS) to prevent Legionella contamination:

FINOLYTE WATER DISINFECTION SYSTEMS

Finanolyte water disinfection systems are designed to disinfect:

- drinking water for municipalities and urban residential areas

- water for the brewing and beverage industry

- dairies and food production facilities

- water in swimming pools and golf courses

- offshore drinking water for airports and shipping companies

- drinking water for restaurants, hotels, hospitals, schools, etc.

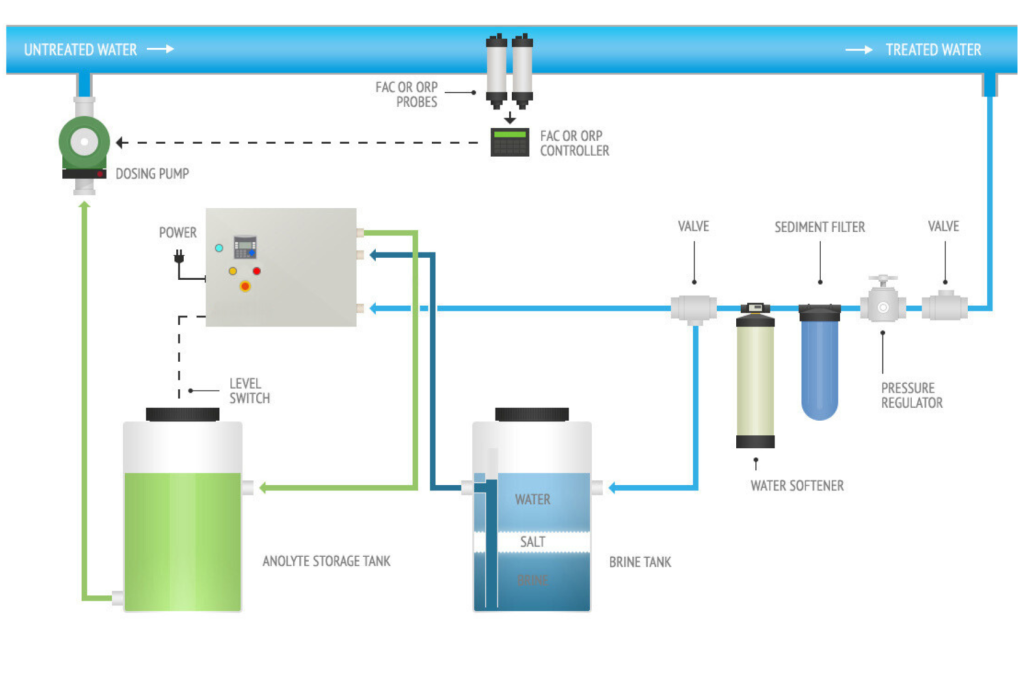

Drawing of a typical Finanolyte water disinfection system (EWDS):

HOW DOES IT WORK?

Each Finanolyte water disinfection system consists of:

- Finanolyte unit (one or more)

- tanks for anolyte and NaCl solution

- dosing pump(s) with FAC or ORP controller

The anolyte produced by the Finanolyte unit is collected in a vessel and then metered into the incoming water (see above). The dosing program depends on the water flow and source water quality (properties) and is controlled either by a flow meter or a FAC/ORP controller connected to the dosing pump.

How is disinfection achieved?

In the Finanolyte unit, an electrochemically activated NaCl aqueous solution, a powerful, non-toxic and harmless disinfectant called Anolyte, is the main disinfectant in all EWDSs.

Anolyte is a colorless transparent liquid with a slight chlorine smell. It contains various mixed oxidants, mainly hypochlorous acid, which anolytes give a highly bactericidal and spore-killing effect.

The anolyte parameters are as follows:

- pH 2.0 to 8.5

- active chlorine concentration (general) 100-6000 mg/l

- very high oxidation activity with small (hundreds of percent) concentrations of working substances that do not harm the chemical and other vital properties of the treated water and do not form toxic compounds.

ADVANTAGES OF FINOLYTE WATER DISINFECTION SYSTEMS:

- Due to the very low concentration of active chlorine, Anolyte diluted in water does not cause toxic effects and does not form toxic by-products.

- Anolyte penetrates the small pores of water pipes or any other material.

- Anolyte eliminates biofilm and algae from the distribution system.

- Water pipes and equipment do not need to be rinsed with water after disinfection.

- Anolyte does not damage the original, natural properties of the water.

- Anolyte removes the taste and smell of chlorine and improves the taste and smell of algae.

- The anolyte can be stored and kept for later use when needed.

- Easy dosing.

- High level of safety: no dangerous chemicals are produced or used.

WHY IS FINOLYTE WATER DISINFECTION TECHNOLOGY BETTER THAN TRADITIONAL CHLORINATION?

- Although seemingly analogous to chlorine, anolyte is unique and clearly superior to sodium hypochlorite in killing spores, bacteria, viruses and other pathogenic organisms on the same residual basis. Sodium hypochlorite at a concentration of 5% is effective only for disinfection, but not for sterilization. Sodium hypochlorite is effective against cysts (Guardia, Cryptosporidium);

- Most pathogens, especially waterborne ones, develop resistance to sodium hypochlorite over time.

- Daily use of anolyte as a water disinfectant for more than ten years showed that microorganisms do not develop resistance to anolyte over time.

- The required contact time of the anolyte is less;

- Sodium hypochlorite loses its activity during long-term storage and poses a potential hazard from gaseous chlorine emissions during storage;

- The anolyte is more soluble;

- The bactericidal effect remains at pH values of 4-9;

- Anolyte is minimally corrosive primarily due to its low concentrations and also due to the elimination of the basic element normally present in sodium and calcium hypochlorite;

- The reaction of anolyte and organics produces about half of the trihalomethanes, as does chlorine;

- Anolyte eliminates existing scale and pathogens and prevents dissolved solids in the water from forming new scale. The biofilm is removed. Parts of the building are not required to be closed from normal use during treatment;

Before dosing the anolyte

After anolyte dosing

Finanolyte Anolyte system does not contain dangerous chemicals or heavy maintenance.

HEALTH CARE

In the 1960s and 1970s, the wholesale use of new (and often underdeveloped) biocides as a weapon against microorganisms in food production and health care was common, and it was not until the 1980s that they were shown to have caused serious biological and environmental harm. Global efforts were made to ban the use of these toxic chemicals, although some remained, such as formaldehyde and its derivatives (when they were withdrawn from medical use as asthma and cancer-causing agents).

Finanolyte has been actively involved in researching the possibilities of anolyte to replace chlorine, which has been the most effective disinfectant for over a century and eradicated many harmful diseases caused by population growth and poor living conditions. However, it has been documented and proven that chlorine combined with organic material produces dangerous carcinogenic products or side effects that do not allow the widespread use of this chemical for safety or environmental reasons.

Anolyte has since been used as a water treatment method in commercial and industrial applications, including human waste treatment and oil exploration, ensuring that waterways and the environment are not the primary source of excessive contamination.

Anolyte, a blend of electrolyzed salt water and water, has been developed by Finanolyte to provide a unique electrolyzed water biocidal fluid that provides the cleaning powers and benefits of chlorine without the dangerous side effects, ensuring no toxic or other side effects to humans or animals.

Since anolyte is biodegradable, it is not harmful to the environment or aquatic organisms.

Finanolyte has also developed the necessary technology and experience to keep the product stable and active in storage for up to 18 months, making it an ideal cold sterilization tool for the healthcare industry, with excellent spore-killing, fungicidal and bactericidal powers at the same time.

Identified hospital applications of anolyte include, but are not limited to:

- Treatments of hard surfaces

- Hand washing

- Soaking and washing the device

- Decontamination of endoscopes and washing equipment

- Cleaning of water reservoirs and pipelines

- Secondary disinfectant according to standard EN15883 / HTM 01

- Foot care – washing instruments and foot soaks

- Radiology – hard surface wiping and ultrasound decontamination

equipment - Bed & Wheelchair Washing [compatible with most UK bed washing machines]

- Laundry pretreatments

- Misting of clean areas – as part of deep cleaning or rapid decontamination

- De-biofilm techniques in endoscopes and dental instruments